Traditional Folding Machines Slowing You Down?

Success Story: U.S. Metal Cabinet Plant Boosts Shipping Efficiency with the Next-Generation Press Brake!

Still operating a conventional folding machine with slow speed and unstable accuracy?

Still spending hours on manual rework after every batch?

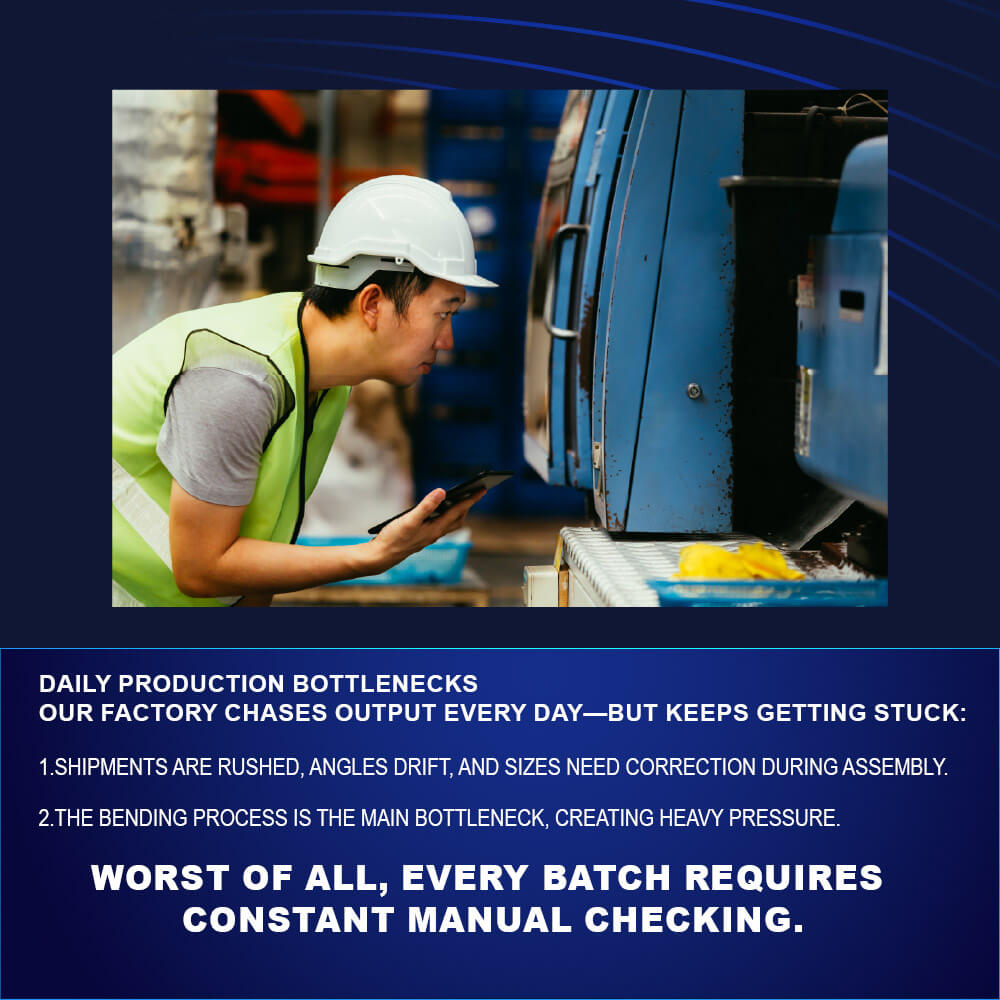

Success Story – U.S. Small/Medium Iron Cabinet Manufacturer 🇺🇸

- 🚧 Shipments under pressure, bending angles inconsistent

- 🚧 Sizes require extra correction during assembly

- 🚧 Production bottlenecked at the bending stage

🚀 Tailift Next-Generation Press Brake = Instant Productivity Lift

- ✅ High-speed, low-noise operation—keep production on schedule

- ✅ Servo-hydraulic precision—angles stay true, no deviation

- ✅ Smart automated interface—easy for new operators to master

- ✅ Smooth assembly, stable production lines—from first bend to final fit

🌟 Trusted by customers across India, Europe, and the U.S.

After seeing our live demo at international expos, many ordered multiple press brakes plus laser cutting systems on the spot! 🎉

Choosing the right equipment saves time, labor, and maintenance costs, making your production line leaner and more competitive.

Ready to Upgrade?

📞 Free Consultation: 0800-066009

🌐 See more real-world success stories: www.tailiftgroup.com/tw

Tailift Sheet-Metal Solutions – Precision and Efficiency in One Stop.

Would you like this adapted for a social media post (shorter, hashtag-friendly) or formatted for a brochure/email?