CNC Press Brake

TCH Series

- CT15 Controller

- Hoerbiger Servo Hydraulic System

- Synchronous Position Feedback On Both Sides With Linear Scale

- The back gauge is equipped with servo motor and high-precision ball screw

Features

Automatic Back Stopper Device

The positioning axis is driven by servo motor and is driven by two sets slide rods. Compact mechanical structure, fast operation speed, high stability and high repeatability positioningaccuracy.The stopper can be moved to the desired position by servo motor. (Automatic movement is optional)

Quick Release and Clamping Device

Quick clamping Device for upper tools, the installation is simple and stable, prevent upper tools falls down, quick release and clamping time, and reduces setting time.

Precision Liner Scale

Minor corrections can be done in the stopper by screws.

Minor corrections can be done in the stopper by screws.

Linear scale feedback actual position and feedback control servo valve at any position.

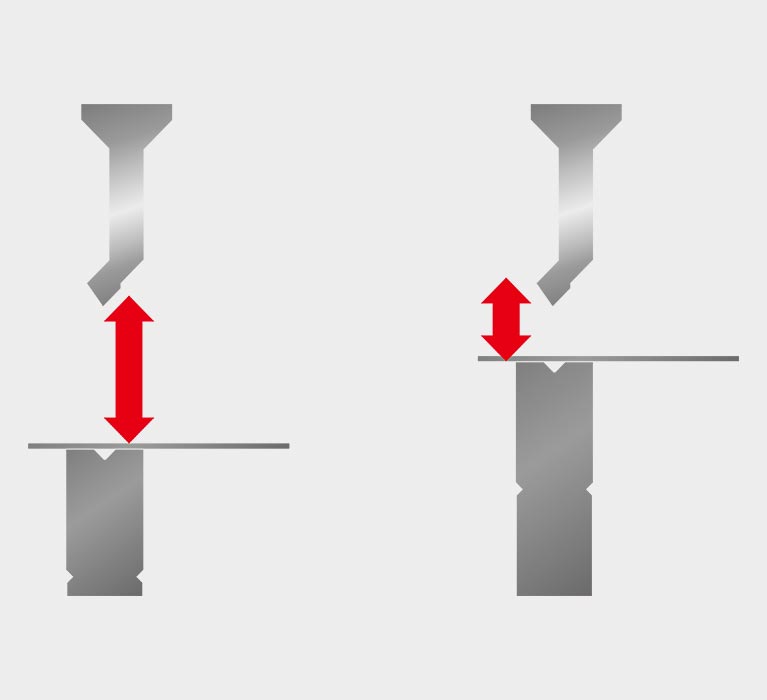

Arbitrary lower limit

Use the Liner Scale to directly control the height of the top beam stop to avoid unnecessary blank strokes.Substantially improve production efficiency.

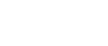

Movable Front Loader Bracket

Fitted in front of the worktable, position of the frontloader bracket can be adjusted manually as requested.

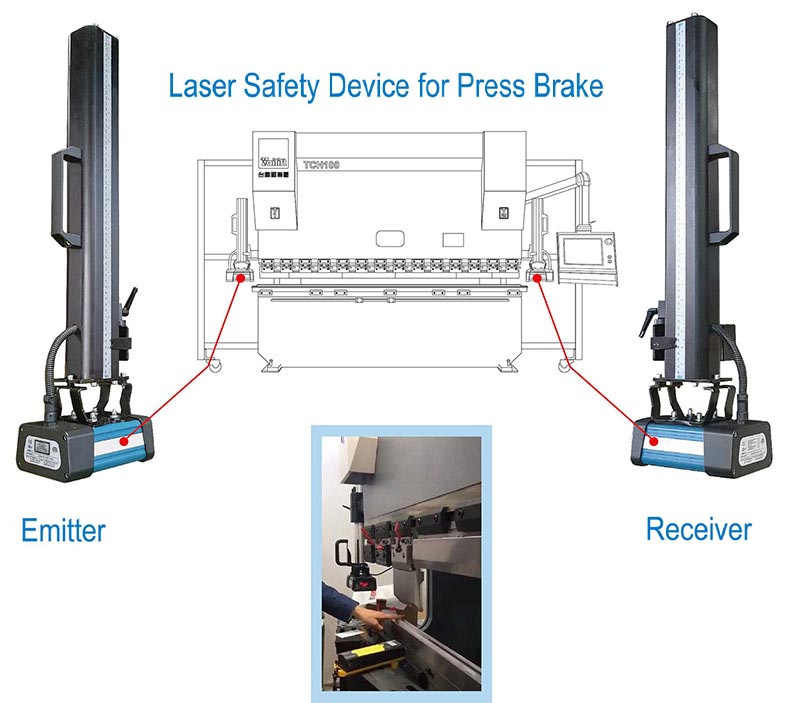

Laser safety device (Option)

Laser safety device protects the press brake operator from the danger of crushing between the moving andfixed part of the machine. The Laser safety device is mounted on the moving part of the machine, and the protection zone moves with the part. When an obstacle is detected, such as an operator fingers, detection is immediate and the machinecan be stopped.

Specifications

| Model | Unit | TCH50 1.6M | TCH70 2M | TCH70 2.5M | TCH100 2.5M | TCH100 3.2M | |

|---|---|---|---|---|---|---|---|

| Force | kN | 500 | 700 | 700 | 1000 | 1000 | |

| Bending Length | mm | 1600 | 2000 | 2500 | 2500 | 3200 | |

| Distance Between Side Frames | mm | 1230 | 1700 | 2100 | 2100 | 2700 | |

| Throat | mm | 260 | 320 | 320 | 320 | 320 | |

| Bending Stroke | mm | 200 | 200 | 200 | 250 | 250 | |

| Effective Open Height | mm | 495 | 495 | 495 | 545 | 545 | |

| Operating Height | mm | 595 | 595 | 595 | 645 | 645 | |

| Drive Motor | kw | 7.5 | 11 | 11 | 15 | 15 | |

| Oil tank Capacity | L | 190 | 230 | 280 | 380 | 380 | |

| X-Axis speed | mm/s | 320 | 320 | 320 | 320 | 320 | |

| R-Axis speed | mm/s | 320 | 320 | 320 | 320 | 320 | |

| Y-Axis Rapid traverse speed | mm/s | 250 | 250 | 230 | 240 | 240 | |

| Y-Axis working speed | mm/s | 12 | 12 | 12 | 11 | 11 | |

| Y-Axis raising speed | mm/s | 200 | 200 | 200 | 180 | 160 | |

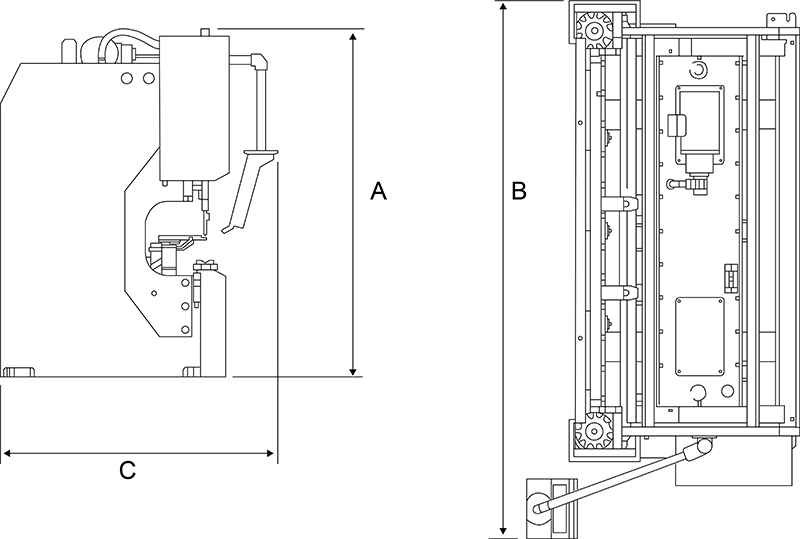

| Dimensions | Length (B) | mm | 1700 | 2250 | 2780 | 3010 | 3710 |

| Width ( C ) | mm | 1480 | 1580 | 1580 | 1670 | 1670 | |

| Height (A) | mm | 2100 | 2130 | 2130 | 2728 | 2720 | |

| Weight | kg | 4000 | 5300 | 6100 | 7800 | 9100 | |

| Model | Unit | TCH100 4.1M | TCH160 2.5M | TCH160 3.2M | TCH160 4.1M | |

|---|---|---|---|---|---|---|

| Force | kN | 1000 | 1600 | 1600 | 1600 | |

| Bending Length | mm | 4100 | 2500 | 3200 | 4100 | |

| Distance Between Side Frames | mm | 3300 | 2100 | 2700 | 3300 | |

| Throat | mm | 320 | 400 | 400 | 400 | |

| Bending Stroke | mm | 250 | 250 | 250 | 250 | |

| Effective Open Height | mm | 545 | 545 | 545 | 545 | |

| Operating Height | mm | 645 | 620 | 620 | 620 | |

| Drive Motor | kw | 15 | 18.5 | 18.5 | 18.5 | |

| Oil tank Capacity | L | 420 | 300 | 330 | 430 | |

| X-Axis speed | mm/s | 320 | 320 | 320 | 320 | |

| R-Axis speed | mm/s | 320 | 320 | 320 | 320 | |

| Y-Axis Rapid traverse speed | mm/s | 220 | 200 | 200 | 200 | |

| Y-Axis working speed | mm/s | 13 | 13 | 13 | 12 | |

| Y-Axis raising speed | mm/s | 160 | 180 | 160 | 160 | |

| Dimensions | Length (B) | mm | 4610 | 3030 | 3730 | 4630 |

| Width ( C ) | mm | 1770 | 1680 | 1680 | 1790 | |

| Height (A) | mm | 2720 | 2720 | 2720 | 2720 | |

| Weight | kg | 8700 | 10100 | 12100 | ||

| Model | Unit | TCH160 5.1M | TCH160 6.1M | TCH200 3.2M | TCH200 4.1M | |

|---|---|---|---|---|---|---|

| Force | kN | 1600 | 1600 | 2000 | 2000 | |

| Bending Length | mm | 5100 | 6100 | 3200 | 4100 | |

| Distance Between Side Frames | mm | 4600 | 5600 | 2700 | 3600 | |

| Throat | mm | 400 | 400 | 400 | 400 | |

| Bending Stroke | mm | 250 | 250 | 250 | 250 | |

| Effective Open Height | mm | 545 | 545 | 545 | 545 | |

| Operating Height | mm | 620 | 620 | 620 | 620 | |

| Drive Motor | kw | 18.5 | 18.5 | 22 | 22 | |

| Oil tank Capacity | L | 430 | 430 | 380 | 420 | |

| X-Axis speed | mm/s | 320 | 320 | 320 | 320 | |

| R-Axis speed | mm/s | 320 | 320 | 320 | 320 | |

| Y-Axis Rapid traverse speed | mm/s | 160 | 150 | 180 | 160 | |

| Y-Axis working speed | mm/s | 12 | 12 | 13 | 13 | |

| Y-Axis raising speed | mm/s | 120 | 110 | 160 | 150 | |

| Dimensions | Length (B) | mm | 5630 | 6630 | 3730 | 4630 |

| Width ( C ) | mm | 1800 | 1800 | 1680 | 1790 | |

| Height (A) | mm | 2960 | 3160 | 2720 | 2720 | |

| Weight | kg | 17000 | 20000 | 10500 | 14100 | |

| Model | Unit | TCH250 2.5M | TCH250 3.2M | TCH250 4.1M | TCH250 5.1M | |

|---|---|---|---|---|---|---|

| Force | kN | 2500 | 2500 | 2500 | 2500 | |

| Bending Length | mm | 2500 | 3200 | 4100 | 5100 | |

| Distance Between Side Frames | mm | 2100 | 2700 | 3300 | 4600 | |

| Throat | mm | 400 | 400 | 400 | 400 | |

| Bending Stroke | mm | 250 | 250 | 250 | 250 | |

| Effective Open Height | mm | 545 | 545 | 545 | 545 | |

| Operating Height | mm | 645 | 645 | 645 | 645 | |

| Drive Motor | kw | 37 | 37 | 37 | 37 | |

| Oil tank Capacity | L | 320 | 400 | 430 | 430 | |

| X-Axis speed | mm/s | 320 | 320 | 320 | 320 | |

| R-Axis speed | mm/s | 320 | 320 | 320 | 320 | |

| Y-Axis Rapid traverse speed | mm/s | 150 | 150 | 130 | 120 | |

| Y-Axis working speed | mm/s | 13 | 13 | 12 | 12 | |

| Y-Axis raising speed | mm/s | 160 | 150 | 130 | 100 | |

| Dimensions | Length (B) | mm | 3050 | 3750 | 4650 | 5650 |

| Width ( C ) | mm | 1920 | 1920 | 1920 | 1920 | |

| Height (A) | mm | 2975 | 2975 | 2975 | 3125 | |

| Weight | kg | 11700 | 14000 | 16000 | 21200 | |

| Model | Unit | TCH250 6.1M | TCH320 3.2M | TCH320 4.1M | TCH320 5.1M | TCH320 6.1M | |

|---|---|---|---|---|---|---|---|

| Force | kN | 2500 | 3200 | 3200 | 3200 | 3200 | |

| Bending Length | mm | 6100 | 3200 | 4100 | 5100 | 6100 | |

| Distance Between Side Frames | mm | 5600 | 3700 | 3300 | 4600 | 5600 | |

| Throat | mm | 400 | 400 | 400 | 400 | 400 | |

| Bending Stroke | mm | 250 | 310 | 310 | 310 | 310 | |

| Effective Open Height | mm | 545 | 600 | 600 | 600 | 600 | |

| Operating Height | mm | 645 | 695 | 695 | 695 | 695 | |

| Drive Motor | kw | 37 | 45 | 45 | 45 | 45 | |

| Oil tank Capacity | L | 460 | 410 | 460 | 460 | 460 | |

| X-Axis speed | mm/s | 320 | 320 | 320 | 320 | 300 | |

| R-Axis speed | mm/s | 320 | 320 | 320 | 320 | 220 | |

| Y-Axis Rapid traverse speed | mm/s | 120 | 110 | 110 | 100 | ||

| Y-Axis working speed | mm/s | 10 | 12 | 12 | 10 | 10 | |

| Y-Axis raising speed | mm/s | 100 | 100 | 100 | 90 | 90 | |

| Dimensions | Length (B) | mm | 6650 | 3930 | 4830 | 5830 | 6830 |

| Width ( C ) | mm | 1920 | 2110 | 2110 | 2150 | 2150 | |

| Height (A) | mm | 3325 | 3205 | 3205 | 3690 | 3855 | |

| Weight | kg | 24600 | 17700 | 20300 | 26100 | 30400 | |

-

specifications are subject to change without prior notice.

Layout