Laser Equipment

Filter the Machine You Need

Select Types

Laser Power Control Function

Table Type

Space Occupied

Type

Applicable Industry

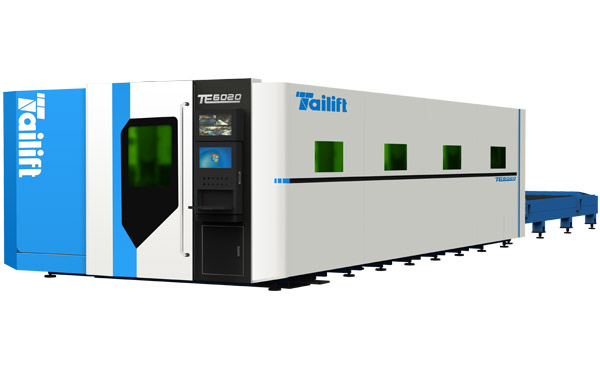

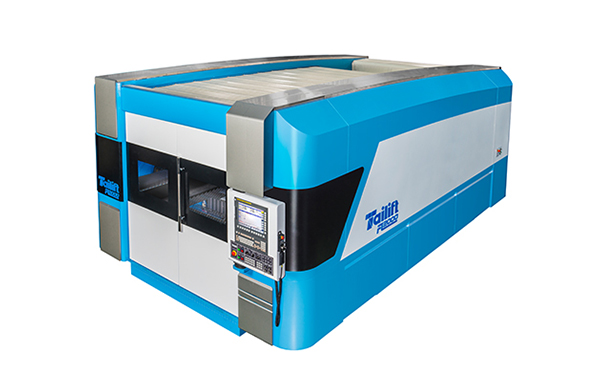

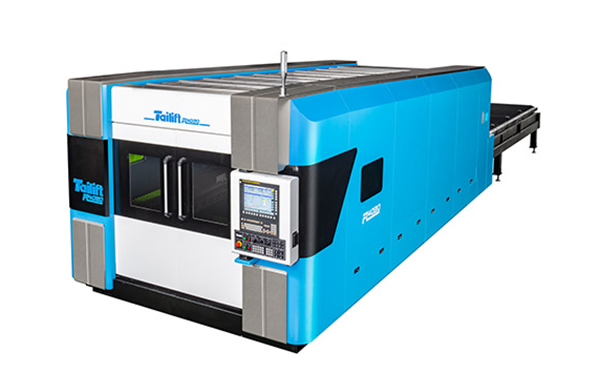

40,000 W Super Model

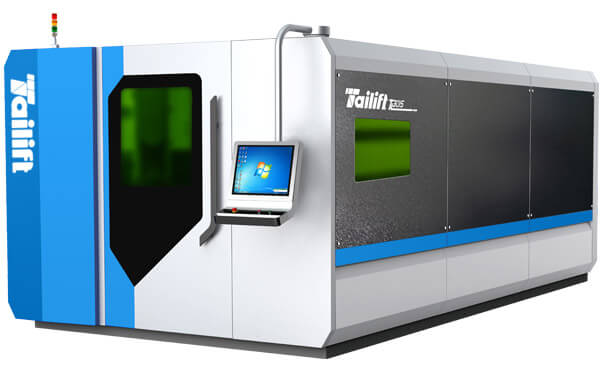

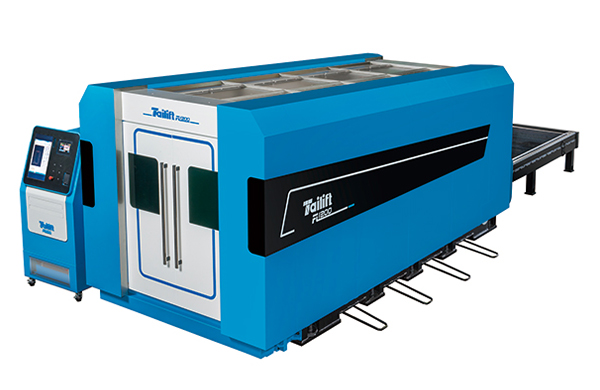

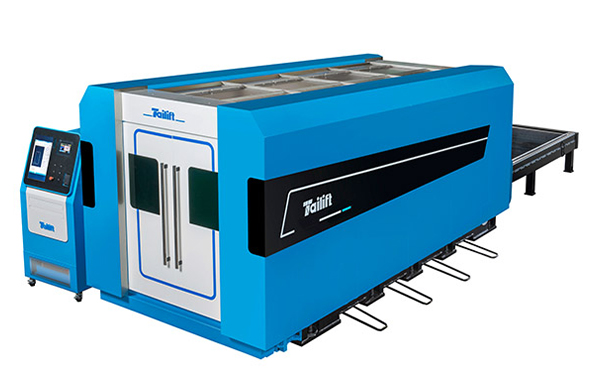

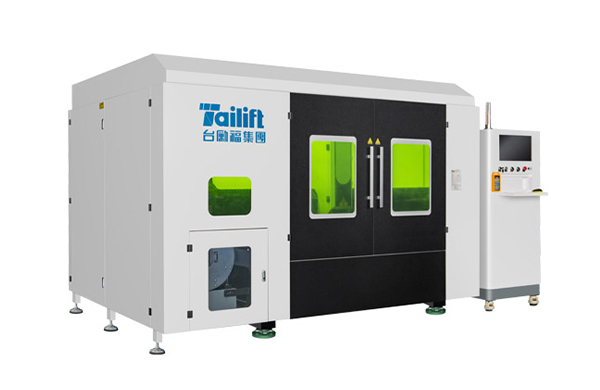

HIGH PRECISION FIBER LASER CUTTING MACHINE

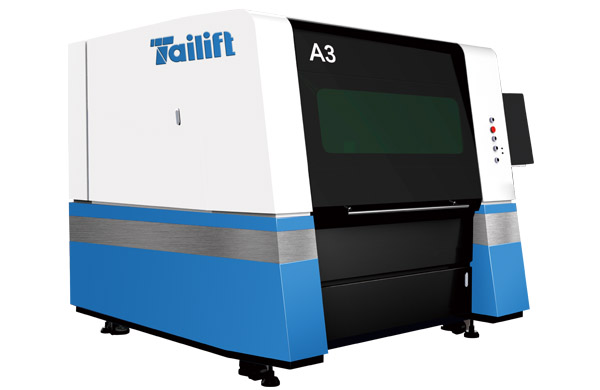

A3 HIGH PRECISION

FIBER LASER CUTTING MACHINE

| Machining range(X*Y) | 1500*3000 |

| Travel(X*Y*Z) | 1525*2050*150 |

| Machining range(X*Y) | 2000*4000 |

| Travel(X*Y*Z) | 2050*4050*200 |

| Machining range(X*Y) | 2000*6000 |

| Travel(X*Y*Z) | 2015*6050*200 |

| Machining range(X*Y) | 3050*1525 |

| Travel(X*Y*Z) | 3100*1550*100 |

The optical fiber laser cutting machine that meets the customer’s requirement.

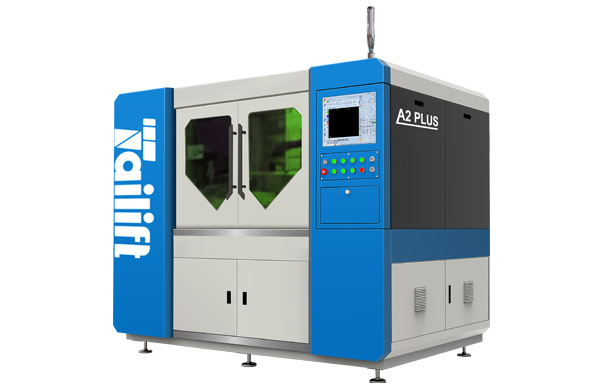

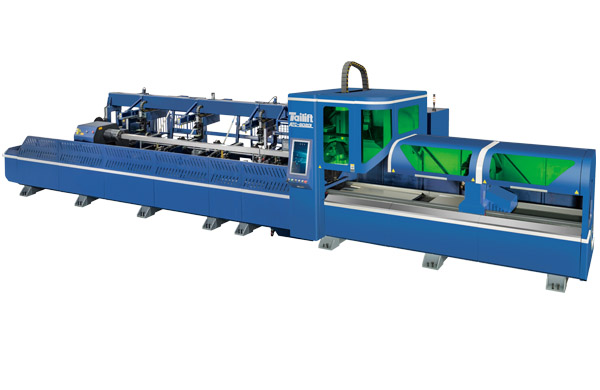

Pipe cutting needs and Metal sheet cutting needs, should I really choose two types of equipment?

Limited budget and limited space for use, but there is a demand for cutting tube and Metal sheet, how to buy an equipment?

- Best

quality and suitable for a small amount of various products

- Full splash guard, safest protection

- OD6 grade fiber optic protective glasses, effectively block the laser radiation

- Sheet and tube compound cutting, one machine for two purposes does not occupy space

- Emergency stop switch, safety protection during operation

- Cuttable tube type: round tube, square tube, triangular tube, oval tube, H type material

Fully enclosed pneumatic chuck, with good dust-proof performance,

double-row wheel claw design, improve cutting accuracy.

Super advantages of "Thin" sheet metal